Oil Management Guide

This

page has been put together to act as a guide for all the people

in the fish frying trade who are interested in getting the

most from their oil. It`s purpose is to cover all aspects

of good oil management and to ensure that you the frier get

the most out of your frying medium. The ten commandments of good oil management can be found on the page below

• SIEVE OUT BATTER SCRAPS CONTINUOUSLY DURING FRYING • FILTER DAILY USING AN EFFICIENT SYSTEM • MELT DOWN SOLID FATS AT LOWER TEMPERATURES (120 C) • ENSURE RAW MATERIALS ARE WELL DRAINED AND FREE OF EXCESS MOISTURE • CHECK THE FUME EXTRACTION SYSTEM FOR OIL BUILD UP ON A REGULAR BASIS • MINIMISE LIGHT AND AIR INGRESS • EMPTY AND DEEP CLEAN THE FRIER ON A REGULAR BASIS • TOP UP WITH FRESH OIL ON A REGULAR BASIS • DO NOT USE COPPER, IRON OR BRASS UTENSILS IN THE OIL

1. Some basic characteristics of oils/fats which need to be taken into consideration

Oils and fats are made up of mixtures of triglycerides and each triglyceride is made up of three fatty acids that are attached to a glycerol molecule.

A saturated fatty acid has no areas of weakness and is thus classed as very stable A monounsaturated fatty acid as its name suggests (mono = one) has one area of weakness and thus only has relative stability However Di and tri unsaturated fatty acids as their name suggests (di = two and tri = three) have two or three areas of weakness and are thus classed as unstable. It is these areas of weakness along the fatty acid molecule that make that particular fatty acid susceptible to reaction with oxygen -This is the second important point to note. So when edible oils and fats are subjected to the frying process they are very susceptible to both. 1. Oxidative breakdown via reaction with Oxygen 2. Hydrolytic breakdown via reaction with water. In addition the frying process is carried out at elevated temperatures which itself leads to Thermal breakdown. We need to be aware that during the frying process all three of these forms of oil degradation are taking place at the same time and so we need to take positive steps to minimise their effect, see section 3 below.

1. Oxygen ( Fryer open to contact with the air) 2. High Temperatures ( Heat required for frying the food) 3. Water ( The food is usually wet when it is fried) 4. Dirt ( Particulate matter, namely frying debris) 5. Light ( Fryer open to contact with light ) 6. Soaps ( Left over from cleaning)

7. Trace metals ( Equipment/utensils contain oxidative catalysts Attack from these sources will lead to the following Physical/ Chemical breakdown Visual Effects include: OIL

OR FAT DARKENS IN COLOUR Chemical Effects: INCREASED FATTY ACID LEVELS

The

Free fatty acid level, colour level, smoke point and flash point

can all be measured analytically, however, in the small frying

trade it is the visual signs that are used to monitor the quality

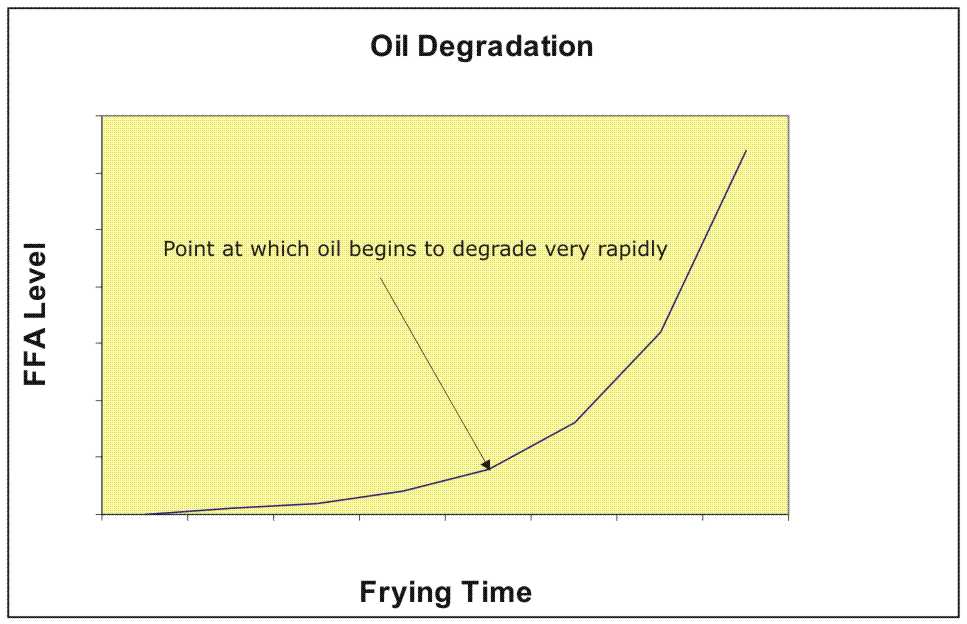

of the oil. There comes a point during the frying process when all these parameters start to accelerate and it is at this point that the oil starts to break down very rapidly

There is a period of reasonable Free Fatty Acid stability beyond which the oil will begin to degrade very rapidy. Pure free fatty acids are used in many technical applications because of their “wetting properties” it is this effect that one observes when one sees a higher then normal absorption of oil into the final fried product and so obviously the higher the percentage absorption into the finished product the greater the bearing the oil has on finished product quality. These raised levels of Fatty Acids are also in direct relationship with the increased frothing and increased smoking. Not only do we see a reduction in product quality but we also increase the risk of either environmental problems through excessive odours or at the worst the risk of a fire. This then leads us into the area of risk reduction and the positive steps we need to take to minimise oil breakdown.

The issues involved in oil breakdown are fairly complex and all efforts should be made to reduce the “loading Effect” against the oil. As the oil is subject to extreme conditions it will inevitably lead to deterioration, the control of which can either extend or reduce the lifetime of the oil. Lets consider each of the factors. a. Frying Temperature and effective control of such. Accurate temperature control is essential, the frying of chips should be done between 170 and 180 C and the frying of fish should be done between 175 and 185 C. These frying ranges are best maintained by the use of a thermostat and it is always good practice to check the accuracy of the thermostat from time to time by the use of a dip thermometer. Frying at too high a temperature will result in food that is darkly coloured plus the breakdown process of the oil will proceed much faster (For every 10C rise in temperature above the recommended frying temperature of 180C the thermal stability of the oil will be halved. Frying at too low a temperature will result in food being too greasy through excessive absorption of the oil. So the key here is for proper and effective heat control – use an accurate and well maintained thermostat. It is also recommended that an automatic safety cut out is installed to ensure the oil is kept well below its flash point and thus reduces the risk of fire.

I think it is fair to say that fish poses very few problems with regard to moisture levels as it is usually left to defrost into drip trays thus leaving very little free moisture on the product. The main cause of oil breakdown thus comes from excessive moisture on the chips. Chips

or other potato products are usually prepared well in advance

of cooking and in some cases potatoes will have a tendency to

discolour if left for any period of time untreated, thus there

are several products on the market which can be employed to

stop this discolouration. So the key here is to ensure the potatoes are well washed after chipping ( to remove all the free starch that has been released) all chips are evenly treated and all treated potatoes are well drained prior to cooking. These steps prevent excess starch and/or moisture making contact with the oil, which will help reduce the speed of oil breakdown.

The main causes of particulate production are, batter scraps, from the frying of battered fish and other food particles mainly starches from potatoes which are insoluble in the oil. The reason particulates are a problem is because they create a large surface area for the oil to react upon, plus the particulates themselves can accumulate, become charred and cause additional breakdown products as well as aid oil polymerisation. It is always good practice to continue to sieve out the batter scraps after each and every frying, however the very minute black specs which can pass through a fairly fine sieve need a much more efficient system for removal and this involves a more sophisticated filtration system. All the pans used for frying should be filtered on a daily basis. In most cases the cleaning system involves removing the hot oil from the pan, cleaning the pan by the removal of any built up brown resinous material and then filtering the oil through a very fine mesh back into the clean pan. Once a week a more thorough clean should be carried out, when the pan is empty it should be given a scrubbing with hot water and detergent. Care must be taken at this point to ensure that all detergent used is thoroughly rinsed away and the frier is completely dry before putting back the oil. So the key here is to have a daily filtration regime which will remove any free particles and a scheduled deep clean which will remove products of polymerisation. In

the section on characteristics of the oil/fat we encountered

the idea of un-saturation. The degree of un-saturation is related

to the relative stability of the oil, so the more unsaturated

the oil/fat has, the more areas of weakness it has and consequently

the more unstable it is. To minimise the effect of light and air the frying range covers should be closed when the fryer is not being used. e. Minimising contact with soaps. It is recommended that the frier is deep cleaned on a regular basis using a soap or detergent. Care must be taken to ensure that all traces of soap/detergent are thoroughly rinsed away as both soap and alkaline detergents generally promote the breakdown of oil. To minimise the effect of soaps always thoroughly rinse and dry the pan before adding fresh oil. Trace metals such as Copper and Iron have a catalytic effect on the oil breakdown i.e they increase the speed at which the breakdown occurs. For this reason you should ensure that all utensils, fixtures and fittings are made from stainless steel. In addition it is recommended that salt is not added to the food prior to frying as the sodium ions from the salt (Sodium Chloride ) also catalyse the oxidation reactions. The key here is to only use stainless steel utensils, fixtures and fittings. 4. Some other considerations a. Top Up One factor that will reduce the increase in breakdown of the oil is that of oil turnover, if the oil is constantly been used up by absorption into the finished product then the pan will need constant topping up with fresh oil. This in turn will keep the oil reasonably fresh and if the rate of replacement is high enough the discarding of oil may not be necessary.

All

vegetable oils contain a level of natural antioxidants, however,

these levels are reduced by some of the processing steps carried

out by the manufacturer. In order to prolong the shelf life

of the packaged product the manufacturer can add synthetic antioxidants

to the oil, which is denoted by an E number declaration. Unfortunately

their effect is only very minimal, as heat and steam (in the

frier) combine to break them down and volatilise them. c. Which oil? Each oil has its own stability profile, however, the manufacturer has at his disposal some means of improving the stability of a less stable liquid oil. The method the manufacturer will use is called Hydrogenation, this process in effect changes the oils characteristics by removing one or more areas of weakness and in doing so the liquid oil becomes more solid. The benefit of this is a medium with a longer life but on the down side the hydrogenated product is more costly and contains a much higher level of “Trans Fatty Acids”. Manufacturers have carried out tests to measure the stability of different types of oil and fat. From the results a table of an oils/ fats stability can be drawn up – see below 1. Hydrogenated Fats = Most Stable 2. Palm oil 3. Groundnut/ Dripping 4. Rapeseed oil = Least Stable

Remember a good tasting product, well presented and packaged at a fair price will go a long way to ensuring customers make repeat visits.

In

this document we have covered the main factors involved in the

frying process. We have looked at some basic oil and fat chemistry

and the role`s heat and oxygen play in oil breakdown. Finally

we looked at some other considerations which need to be taken

into account when choosing the correct frying medium, customer

preference and geographical region being the most important. |

||||||